Pioneering Precision: China's Role in Revolutionizing the Injection Mold Arena

The manufacturing industry in China is well-known around the world, especially when it comes to injection molding. Being the world's largest plastic injection mold maker, China has definitely created an impact and brought changes to the injection mold sector. This influence is present in several industries including automotive, consumer electronics and medical devices where precision and efficiency are uncompromising. This article focuses on the fact that China has transformed the way injection molding is conducted, giving rise to industries with unmatched capacities and cutting-edge innovations.

Technical Development

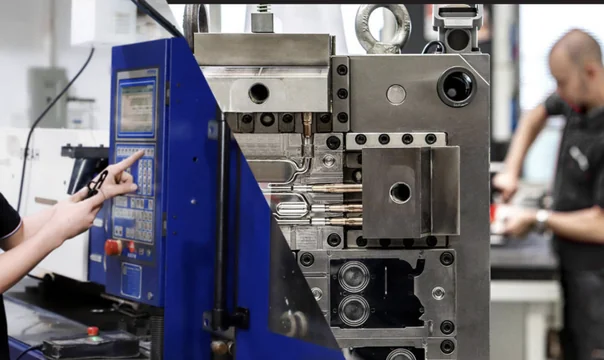

The injection mold sector in China has a good reputation for its high-tech level, including CNC machine tools, precise laser cutting, and quality control automation. These technologies allow the Chinese plastic injection mold makers to create molds that not only have high accuracy but are also sturdy and able to withstand the rigors of mass production.

Driving Innovation

R&D is the key pillar of the Chinese strategy to maintain its leadership in the injection molding industry. Extensive R&D investments make Chinese plastic injection mold makers able to keep pace with the development of new materials that are stronger, lighter, and more eco-friendly. This continuous innovation brings the production methods closer to perfection and the quality of a product to a higher level.

Scale of Production

The scale of production at Chinese mold manufacturing plants is incomparable. These plastic injection mold makers with large plants, fully equipped with the most advanced molding equipment, can process orders of any size at an unbeatable speed that has become an industry benchmark. These capabilities enable them to satisfy the global market fast, thus making them the first choice for international businesses.

Quality and Precision

Quality is the signature of Chinese manufacturing and mould company industry is the best evidence for this. All molds are subjected to rigorous testing and quality assurance practices where each mold is required to meet strict standards before being deployed into production. This care and attention to detail ensures that the finished products are of the best quality, which is essential in applications where precision is a critical factor, like in the medical devices and aerospace components.

Global Supply Chain Integration

The injection mold manufacturers of China, besides being the main players in the domestic market, are also the core parts of the global supply chain. Through offering not only reliable and top quality molds but also the competitive price, they support many industries worldwide. Their ability to fit into different supply chains makes them the most needed in the global market.

China's role in the development of the injection molding industry embodies its overall ambition to be at the forefront of manufacturing excellence and innovation. This leadership is why China is still the leader of the injection mold field, which is going to change the world's manufacturing trends.