Efficient fluid handling is essential for industries like manufacturing, agriculture, and food processing. However, challenges such as leaks, inefficiency, and difficulties with viscous or corrosive liquids often hinder operations. Poorly chosen pumps exacerbate these issues, leading to costly downtime, operational disruptions, and increased maintenance expenses.

Selecting the wrong pump impacts system performance and operational budgets. Unsuitable equipment may fail to handle specific fluids or meet safety requirements, causing ongoing frustration and inefficiency. This makes choosing the right pump a critical decision for professionals in fluid-handling industries.

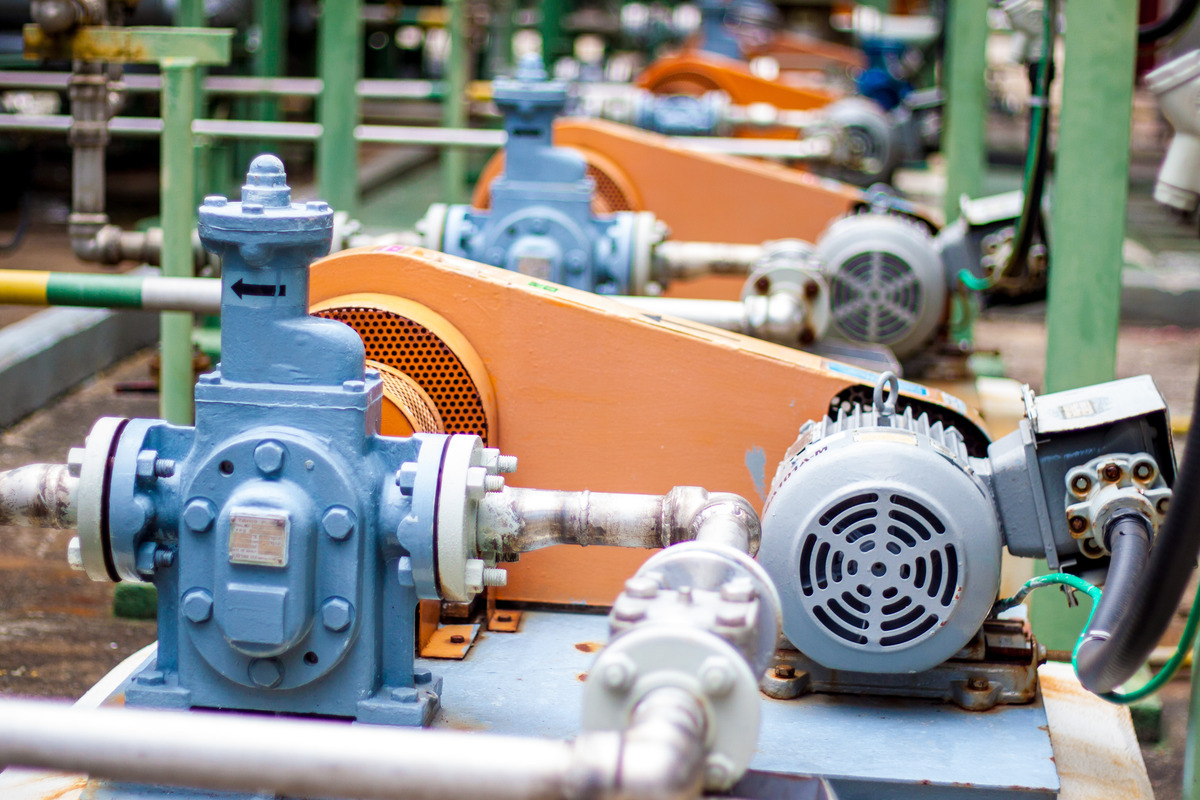

Diaphragm pumps offer versatile and reliable solutions for these challenges. Their ability to handle a wide range of fluids, combined with leak-free operation and durability, makes them an excellent choice across various industries. Understanding their functionality and applications helps ensure optimal performance and efficiency.

Understanding the Basic Mechanics of Diaphragm Pumps

A diaphragm pump is a positive displacement pump designed for versatile fluid handling. It uses a flexible diaphragm to create suction and discharge cycles. Key components include the diaphragm, valves, and pump casing. The diaphragm separates the fluid chamber from the drive mechanism, preventing leaks and contamination. Valves ensure unidirectional fluid flow, while the casing houses and protects the internal parts.

How Diaphragm Pumps Work

Diaphragm pumps operate through alternating suction and discharge cycles. The diaphragm moves back, creating a vacuum that draws fluid into the pump chamber. As the diaphragm moves forward, it compresses the fluid, forcing it out through the discharge valve. Pressure differentials drive these cycles, ensuring smooth and efficient fluid transfer. This mechanism allows diaphragm pumps to handle various fluids, including viscous, corrosive, or abrasive liquids, with ease.

Types of Diaphragm Pumps

There are three main types of diaphragm pumps: air-operated, mechanically driven, and hydraulically driven. Air-operated diaphragm pumps use compressed air to move the diaphragm, making them suitable for explosive environments. Mechanically driven diaphragm pumps use motors or mechanical linkages for diaphragm movement, offering precise control. Hydraulically driven diaphragm pumps rely on hydraulic fluid pressure, ensuring high power and efficiency for demanding applications. Each type serves specific operational needs and offers distinct advantages.

Benefits of Using Diaphragm Pumps

Diaphragm pumps excel at handling a wide range of fluids, making them indispensable in various industries. They can pump abrasive fluids without causing internal damage, ensuring reliable performance over time. Their design also allows for safe transfer of corrosive liquids, such as acids or chemicals, without risking contamination or degradation. Additionally, they handle highly viscous substances like oils, syrups, and slurries efficiently, meeting complex operational requirements.

Leak-Free Operation

The sealed design of diaphragm pumps prevents fluid leaks, making them a safe choice for sensitive applications. This feature is particularly important when working with hazardous or environmentally harmful substances. The leak-free operation also helps maintain clean work environments and minimizes the risk of fluid loss, reducing overall operating costs.

Durability and Longevity

Built with robust materials, diaphragm pumps are designed to withstand harsh conditions. Their components are resistant to wear and corrosion, ensuring long-term reliability. They require minimal maintenance compared to other pump types, which saves time and reduces operational downtime. This durability makes them a cost-effective solution for demanding industries.

Energy Efficiency

Diaphragm pumps consume less energy than many other pump types, improving operational efficiency. Air-operated models, for instance, do not require electrical power, which is ideal for remote or hazardous locations. Their efficient use of power also contributes to lower energy bills, making them an environmentally friendly and economical choice for fluid-handling needs.

Common Applications of Diaphragm Pumps

Diaphragm pumps have many uses, as outline below:

Industrial Uses

Diaphragm pumps are widely used in industrial operations due to their adaptability and efficiency. In chemical processing, they handle aggressive or corrosive chemicals safely. Their leak-free design ensures safety when managing hazardous materials. Additionally, diaphragm pumps are essential for paint spraying applications, delivering consistent flow and precise pressure for high-quality finishes.

Food and Beverage Sector

The food and beverage industry relies on diaphragm pumps for hygienic and efficient fluid transfer. These pumps handle food-grade liquids such as syrups, oils, and juices without contamination. Their non-reactive materials maintain product purity, meeting strict sanitary regulations. Furthermore, they support operations that require gentle handling of delicate fluids to preserve quality.

Water Treatment and Filtration

In water treatment, diaphragm pumps play a crucial role in managing wastewater and sludge removal. They pump high-viscosity sludge efficiently, ensuring smooth operations. Diaphragm pumps are also used for chemical dosing, delivering precise amounts of treatment chemicals to purify water. Their reliability and ability to handle abrasive fluids make them ideal for this sector.

Agriculture and Irrigation

In agriculture, diaphragm pumps are valuable for spraying pesticides, fertilizers, and water. They ensure accurate and uniform application, which is vital for crop health and growth. Their ability to handle viscous and abrasive substances, like liquid fertilizers or wettable powders, ensures reliability in demanding agricultural tasks.

Conclusion

Diaphragm pumps are a versatile and reliable solution for complex fluid-handling needs. Their ability to handle diverse fluids, ensure leak-free operation, and offer durability makes them essential in industries like manufacturing, agriculture, and water treatment. Their simple yet efficient working mechanism ensures consistent performance across various applications.

Their reliability and adaptability make them the go-to choice for challenging environments and demanding processes. Whether it's managing hazardous chemicals, food-grade fluids, or abrasive sludge, diaphragm pumps excel in maintaining efficiency and safety.

To get the best results, implement a regular maintenance schedule to extend the pump's lifespan and maintain peak efficiency. Consulting experts or manufacturers before purchase ensures you select the right type of pump for your specific requirements. With proper care and informed choices, diaphragm pumps can significantly enhance operational efficiency and reduce costs.